European composites industry set for slow recovery

23 November 2009

From Reinforced Plastics

exhibition

COMPOSITES EUROPE 2009 in Stuttgart.

COMPOSITES EUROPE 2009 took place in Stuttgart on 27-29 October. We review the show news.

The COMPOSITES EUROPE 2009 trade show attracted over 6100 visitors to Stuttgart, Germany, in October, a 48% increase on the number of visitors in 2007 (the last time the show was held in Stuttgart). There were 313 exhibitors at the show.

A survey was taken by an independent market research institute during the fair to determine the industry’s outlook to be positive. Over 60% of the companies interviewed expect a pronounced increase in orders. Another 27% expect the economic situation to remain stable, while less than 10% of companies interviewed believe that sales will deteriorate further.

Green racing. The Renault Mégane Trophy BioConcept Car employs natural fibre composites and is fuelled by biodiesel.

The European composites market

The German federation of reinforced plastics, AVK, released its latest statistics for the European composites industry at the International AVK Conference which marked the start of COMPOSITES EUROPE. According to Dr Elmar Witten, AVK’s Managing Director, by the end of 2009, the production volume of the European market analysed in its survey will probably have dropped by about a third from that of 2007. However, not all market segments are feeling the crunch in the same way, he notes, and companies are making considerable efforts to embrace opportunities in existing markets as well as new ones.

In the AVK survey, the European market analysed was limited to those countries familiar to the raw materials suppliers interviewed. The figures focus only on glass fibre reinforced plastics (GRP).

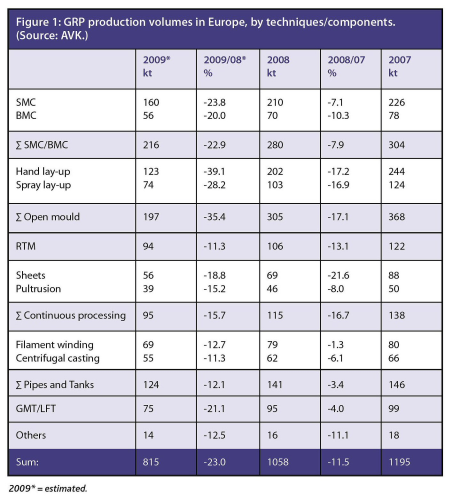

Figure 1: GRP production in Europe, by technique/component. (Source: AVK.)

In 2009, GRP production volumes in Europe are expected to reach 815 000 t (Figure 1), about 30% down on 2007. (However, Witten notes that over shorter time frames, information obtained from raw materials producers on which this data primarily relies may deviate from the volumes actually processed during this time period.)

The demand for, and production, of thermosetting component parts made of SMC (sheet moulding compound) and BMC (bulk moulding compound) were affected by developments in their main application markets – automotive and electronics/electrical equipment. Vehicle production decreased by as much as 50% in some cases, accompanied by even greater losses in the truck sector, necessitating a structural reorientation of the key players in this market segment.

Processors using open moulding techniques (hand lay-up and spray-up) have been hit hard. At the same time, the contribution of these processing techniques to the entire composites production volume has dropped from almost 30% to less than 25%.

Closed moulding (resin transfer moulding) has seen less of a decline. This may be attributed to the substitution of open moulding techniques as well as the low-volume production of component parts with large surface areas.

The market for pultruded GRP profiles in particular is holding its ground relatively well, primarily as a result of new infrastructure projects.

The partially publicly funded building sector (including EU subsidies), as well as new sales territories (especially in Eastern Europe) have slowed the decline in the GRP pipe and the tank building sector. Select niche markets, such as sewer lining, continue to realise high growth rates.

Production of thermoplastic moulding compounds and semi-finished products depend largely on the development of the automotive sector and are showing corresponding setbacks.

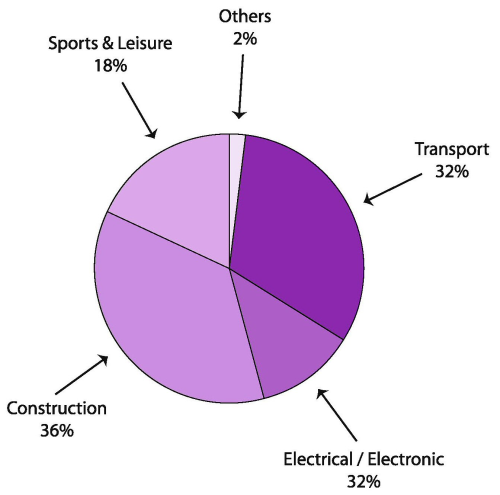

Figure 2: GRP production in Europe by application. (Source: AVK.)

According to the AVK’s statistics, the breakdown of the European composites market in terms of application industries is in general much the same as in previous years (Figure 2). A slight decline in the transport industry has been compensated for by a minor increase in the building sector. In general, the recession in Europe has affected almost all areas of application to a similar degree.

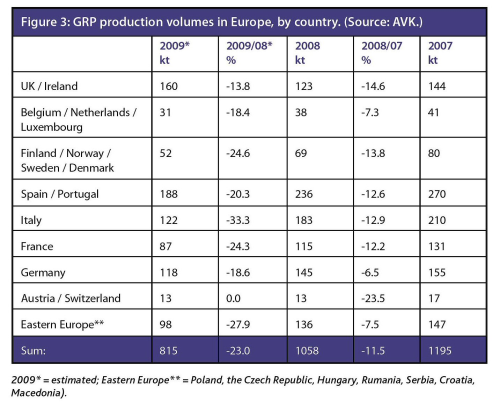

Figure 3: GRP production in Europe by country. (Source: AVK.)

The distribution of the total GRP production volume over the European countries included in the AVK analysis is shown in Figure 3. Heading the list of large players in the European market are Spain, Italy, Germany, the UK and France, whose share in the total volume has increased from approximately two thirds to almost 75%.

Outlook

According to AVK’s estimates, production volumes in the European GRP market will probably not return to 2007/2008 levels until 2013/2014. In many European countries, the composites market is expected to suffer some downsizing in 2010.

Innovation

AVK also presented its awards for outstanding developments in reinforced plastics during the event. The prizes were awarded in four categories.

In the Industrial category, Volkswagen (VW) AG and the Technical University of Dresden (TU Dresden), Germany, shared the first prize with the BMW Group.

Car maker VW and the Institut für Leichtbau und Kunststofftechnik (Institute for Lightweight Construction and Plastics Engineering) at TU Dresden presented their thermoplastic hybrid structures. These are structural components made of plastic and reinforced with local textile inserts (thermoplastic glass fibre prepregs) in areas exposed to high levels of stress. Using this construction, it is possible to substitute highly stressed, structural metal components with lower weight plastic parts.

An example of this technique is a Volkswagen seat pan made using a production method that combines the economic series production technique of compression moulding long fibre reinforced thermoplastics, with inserts reinforced with endless fibres. The seat pan consists of long glass fibre reinforced polypropylene (PP) and features PP inserts reinforced with endless glass fibres in areas likely to be affected by crashes and in places where force is applied. It meets the mechanical requirements of the technical specification and enables a 45% weight reduction compared to conventional seat pans made of steel.

BMW's composite cross-beam.

BMW’s award was for the development of a composite transmission cross-beam. Until now transmission cross-beams for BMW cars have been made of diecast aluminium. The part is required to fulfill performance characteristics such as operating strength, heat management, acoustics, and crash behaviour. To reduce the part's weight BMW wanted to see if it was possible to make the component from glass fibre reinforced plastic.

A selection of composite materials were evaluated, and the injection moulding technology using polyamide (PA) 66 and 50% glass fibre was selected for further development.

The first application for the composite transmission cross-beam is the new BMW 5Series GT. The space required and mounting concept are identical to that for the aluminium part previously used. The weight reduction achieved is approximately 1 kg.

DSM Dyneema BV and DSM Composite Resins AG, in collaboration with DoKaSch ACE GmbH, won the award in the Environment category for an air cargo container made using composite panels.

DoKaSch air cargo container manufactured from composite panels.

Following two years of trials, DoKaSch, a manufacturer of air cargo equipment, introduced the AKE Iw-65 air cargo container, which is made using RP10 composite panels employing DSM's Dyneema® fibre and Aeronite® resin. The container is around 20% (15.5 kg) lighter than standard aluminium containers, leading to reduced fuel use and emissions. The RP10 panels are also up to four times stronger than aluminium sheet and have excellent resistance to impacts and wear and tear which helps to lower maintenance costs.

Based on the success of the AKE (lower deck) container, DoKaSch has added the AKH (main deck) container to its lightweight container range, and this also employs composite panels.

IKV's gap impregnation process.

The Institut für Kunststoffverarbeitung (Institute of Plastics Processing) at the RWTH Aachen (IKV) won the University category for studies into the automatic and large-series production of continuous fibre reinforced plastics parts by the gap impregnation technique (a variant of resin transfer moulding).

The gap impregnation process is a means of speeding up the impregnation of the preform. Unlike an RTM mould, the geometry of the mould cavity can be changed during the process and a flow gap for fast distribution of the resin can be created on top of the preform. To achieve high fibre content the preform can be compressed by a movement of the mould sections.

A prototype gap impregnation process was developed at IKV in cooperation with Hille Engineering. It has been demonstrated that parts of dimensions 500 x 500 mm2 with fibre volume contents of 50% can be manufactured in cycle times of under 10 minutes. Impregnation and compression only take 19 seconds, a significant reduction compared to the RTM process.

IKV believes this process would be of benefit to the automotive, transportation and aerospace sectors.

And finally, AVK awarded cpm composite products mücke a special prize for its Splash Car, a recreational, all-terrain electric vehicle. The main component of the vehicle is a lightweight tub made of a fibre reinforced epoxy resin with a foam core.

The Splash Car.

The car is powered by 4 kW electric motors and steered using a joystick control. Lithium-polymer battery technology allows up to one hour of operation at full power and speed (40 km/h). The car is very economic to operate, and unlike vehicles such as motorbikes, karts and quad bikes, the SplashCar does not produce any noise or exhaust emissions. Potential uses for the car could include a fun vehicle for leisure parks, hotels and individual users, and for observing wildlife.

Also focussing on innovation were DSM Composite Resins, Dieffenbacher and Fraunhofer ICT, who unveiled a direct compounding technology for the production of thermoset composite components.

The new technology is particularly suited to the production of geometrically complex, large (greater than 3 m2) parts in high volumes (approximately 700 000 units per year). The organisations believe the process will open up new opportunities for thermoset composites in replacing metal materials in the automotive industry and other markets.

The result of many years of research and development in European project, the technology has been realised through a strategic cooperation between the three partners. Dieffenbacher, a German manufacturer of press and production systems for processing composite automotive components, developed the hardware systems and expertise. The Fraunhofer ICT industrial research institute of Germany provided R&D and pilot processing capabilities. DSM Composite Resins, headquartered in Switzerland, contributed resin formulation expertise, including the development of a product portfolio of non-thickening resins.

The direct compounding process for thermoset composites unveiled by DSM Composite Resins, Dieffenbacher and Fraunhofer ICT.

A pilot plant is currently operating at the ICT. The first production line is in development and should be operational in the second quarter of 2010.

The technology can produce moulded thermoset compound materials in a continuous and flexible extrusion process (see diagram). Key features include a computerised dosing system yielding better quality consistency and reproducible fibre impregnation. The process results in shorter cycle times through just-in-time production and eliminates a range of steps in between such as paste mixing, thickening and storage compared to conventional thermoset compounding processes, saving time and making part manufacturing more economical.

A spotlight on bio-materials

Sustainability, bio-materials, and all things environmental were high on the agenda at this year’s event.

For its pioneering work in the area of natural fibre reinforced plastics, the BioConcept Car project of Four Motors GmbH was presented with the COMPOSITES Pioneer Award 2009. The body of the BioConcept race car is made almost completely from bio-composite materials: doors, mudguards, bonnet, bumpers, wings and the boot lid are made from natural fibre reinforced plastics. It is fuelled by biodiesel.

Race car team Four Motors GmbH of Reutlingen, Germany, first used a racing car with a body shell made using plant fibres in 2006. This first-generation BioConcept Car was based on a Mustang GT RTD. In 2009 the concept wad developed further in a Renault Mégane Trophy 09. In cooperation with the Nachwachsende Rohstoffe eV (Agency for Renewable Resources) and the German Aviation and Aerospace Centre (DLR), the car’s glass fibre body shell is currently being replaced step by step with parts based on natural fibres. The natural fibres are combined with liquid bioplastic (linseed oil acrylate).

Both cars will take part in upcoming long-distance races.

Both generations of the BioConcept Car – the Mustang and the Renault Mégane Trophy – were on display at COMPOSITES EUROPE 2009.

Also highlighting sustainable composites, the European Composites Industry Association (EuCIA) introduced three new EU-financed projects. EuCIA is a partner in three projects under the European Community’s Seventh Framework Programme:

o NATEX – Natural Aligned Fibres and Textiles for Use in Structural Composites Applications;

o BioStruct – Advanced Wood-Based Composites and their Production; and

o Woody – Innovative Advanced Wood-Based Composite Materials and Components.

All three projects aim to develop sustainable composites based on natural resources.

EuCIA also highlighted the compliance of composites recycling with EU legislation. Following studies into the recycling of composites and consultations with EU institutions and industry stakeholders thermoset composite parts are now considered recyclable and compliant with EU legislation. A joint position paper has been drafted by EuCIA, the European Plastics Converters (EuPC) and the European Composite Recycling Services Company (ECRC) to highlight this approach.

A range of flax fibre based products were introduced by Composites Evolution, Chesterfield, UK, at the show. The Biotex products include commingled flax/polypropylene (PP), commingled flax/polylactic acid (PLA), and flax yarns, fabrics and preconsolidated sheets which could be processed in a variety of composite products. Flax fibres are renewable and have a low environmental impact during processing.

The Biotex materials are based on twistless yarns with long, aligned fibres to exploit the inherent mechanical properties of flax in load-bearing applications, with the added advantage of having a lower weight than conventional reinforcements such as glass fibres.

The Biotex flax/PP and Biotex flax/PLA commingled materials include an intimate blend of the reinforcement fibre and matrix polymer for easy processing by vacuum consolidation or press moulding. The matrix in commingled Biotex flax/PLA is also derived from crops, giving a 100% renewable material that can also be recycled or composted at the end of its life.

Challenges

AVK’s Elmar Witten sees the composites industry facing three major challenges: "The image and level of recognition of materials, innovation in products and processes and proof of sustainability of reinforced plastics - these are the challenges every company must take up. Doing so will create good prospects for the future and growth opportunities in the composites market.

COMPOSITES EUROPE 2010 will take place in Essen, Germany, on 14-16 September, alongside the Aluminium World Trade Fair and Congress.

[upload=1] |

|玻璃钢复合材料商城|联系我们|Archiver|手机版|小黑屋|

FRP玻璃钢复合材料论坛

蜀ICP备10204395号-1

|玻璃钢复合材料商城|联系我们|Archiver|手机版|小黑屋|

FRP玻璃钢复合材料论坛

蜀ICP备10204395号-1